Full range of products

Exquisite workmanship

Rich industry experience

High quality service

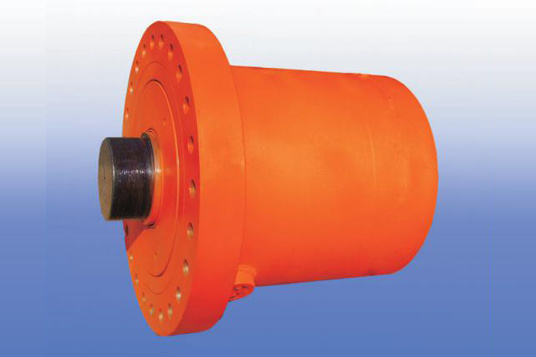

Hot Products

With mighty technical support, powerful design and development ability

Hot Products

With mighty technical support, powerful design and development ability

Shenlu Hydraulic

Focusing on the manufacturing of hydraulic components

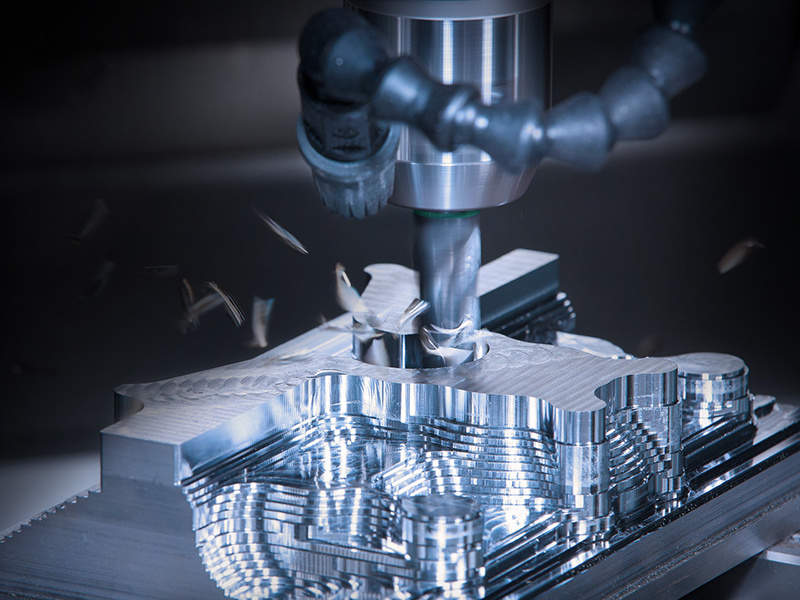

Wuxi Shenlu Hydraulic Machine Parts Co., Ltd is located in Yangshan Town, Wuxi City, Jiangsu province. It is a professional manufacturer that specialized in producing φ32-φ1600 cylinder tubes, φ6-φ1600 piston rods and hollow piston rods for cylinders, hydraulic cylinders, pneumatic cylinders, high precision honing machines, hydraulic cold drawing machines, skiving and burnishing machines, hydraulic pressing machines and various spare parts accordingly. With mighty technical support, powerful design and development ability, we are at the front of this field and receive many good reputations.

Quality Assurance

We have many years of export experience and sold to more than 40 countries.

The application of domestic advanced industrial technology

We have our own stong team to research, design, produce and sell.

We have passed the certification. standard, stable, reliable.

How to improve the surface finish and quality of stainless steel honed tubes?

Knowledge Popularization of CNC Cutting and Polishing Machines

The impact of a large temperature difference between the inside and outside of a non-standard oil cylinder.

What is an oil cylinder? What is its working principle?

Global Service

A after-sales service group will be set up immediately by our engineers, after you received the machine. If there is any problem, our engineers can provide you efficient and high-quality solutions.

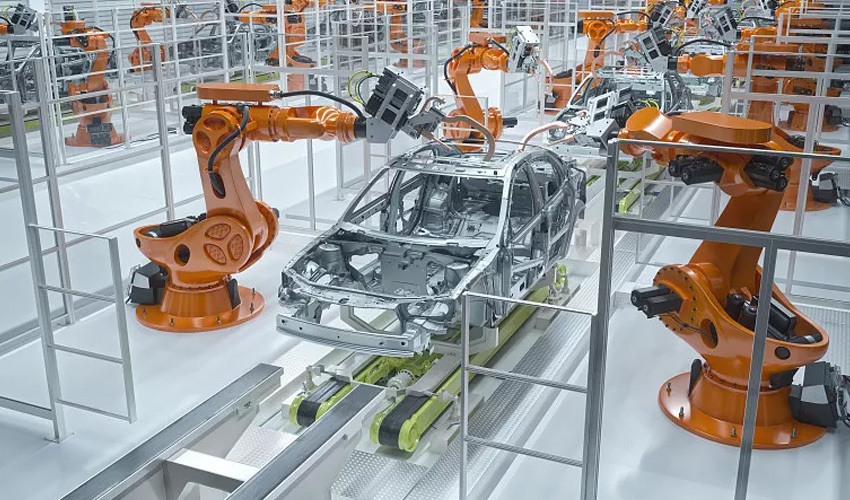

Application Area

With mighty technical support, powerful design and development ability

News Center

With mighty technical support, powerful design and development ability