CONTACT US

SHENLU HYDRAULIC

Tel: +86-0510-83050688

Tel: +86-0510-83959581

E-mail: sales@shenlu.net.cn

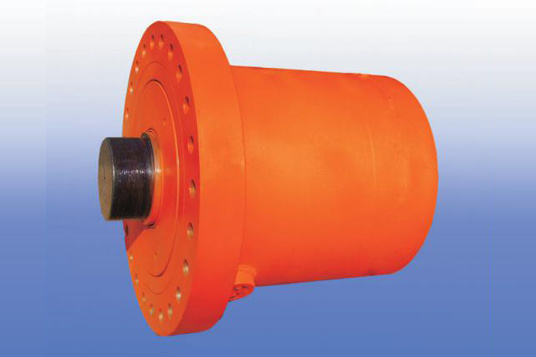

Cylinder

Description

Unlike non-standard oil cylinders, the end cover is equipped with intake and exhaust ports, and a buffering mechanism is set on the end cover. The sealing ring and dust-proof ring are placed on the side cover of the rod to prevent air leakage from the piston rod and to prevent external dust from entering the cylinder. A guide sleeve is set on the side end cover of the rod to improve the guiding accuracy of the cylinder, bearing a small amount of lateral load on the piston rod, reducing the bending of the piston rod, and extending the service life of the cylinder. The internal combustion engine cylinder body is equipped with a cavity for the piston. It is the trajectory of the piston movement, where gas burns and expands. Through the cylinder wall, some explosive waste heat from the gas can also be dissipated, keeping the engine at a normal operating temperature. The cylinder types are integral casting and single-piece casting. Single-piece casting can be divided into dry type and wet type. When the cylinder and cylinder body are cast together, it is called an integral cylinder. When the cylinder and cylinder body are cast separately, the single cylinder is called a cylinder sleeve. The cylinder sleeve that directly contacts the cooling water is called a wet cylinder sleeve, while the one that does not directly contact the cooling water is called a dry cylinder sleeve. To maintain the tightness of the cylinder piston contact and reduce the friction loss of piston movement, the inner wall of the cylinder should have high processing accuracy and accurate shape dimensions.

Product Parameters

Model | JLB150T | JLB250T | JLB300T | JLB400T | JLB600T | JLB1000T | |

Maximum Pulling Force (KN) | 1630 | 2700 | 3200 | 4100 | 6500 | 12000 | |

Drawing Speed (M/min) | 0-5.5 | 0-4.5 | 0-4.5 | 0-4 | 0-3 | 0-3 | |

Effective Length of Finished Pipe (M) | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | |

Finished Pipe Drawing Thickness (mm) | 20 | 25 | 30 | 33 | 42 | 70 | |

Main Oil Cylinder (mm) | Φ320/Φ 150x10000 | Φ420/Φ 210x10000 | Φ450/Φ 210x10000 | Φ500/Φ 220x10000 | Φ630/Φ 280x10000 | Φ850/Φ 350x10000 | |

System Station Count (Station) | 2 | 2 | 2 | 2 | 2 | 2 | |

System Working Pressure (Mpa) | 26 | 26 | 26 | 26 | 26 | 26 | |

System Maximum Pressure (Mpa) | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | |

Pump (Manual Variable Plunger Pump) | 160Lx3 | 160Lx2 250Lx1 | 250Lx3 | 250Lx3 | 250Lx3 | 400Lx3 | |

Main Motor (KW) | 55x3 | 55x2 75x3 | 75x3 | 75x2 90x1 | 90x3 | 132x3 | |

Dimensions (WxHxL) | 1.6x1.4x42 | 1.7x1.5x44 | 1.7x1.5x44 | 1.9x1.8x45 | 2.1x2x45 | 2.65x2.65x60 | |

Weight (T) | 86 | 100 | 120 | 180 | 220 | 300 | |

Keyword:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products