CONTACT US

SHENLU HYDRAULIC

Tel: +86-0510-83050688

Tel: +86-0510-83959581

E-mail: sales@shenlu.net.cn

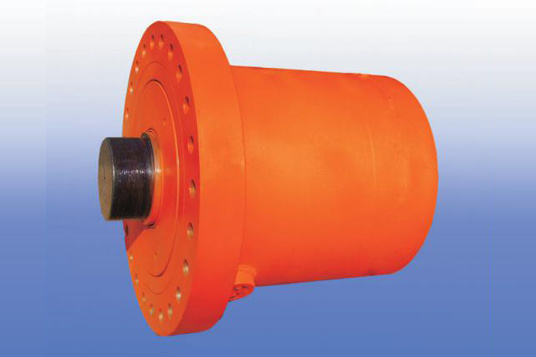

Cylinder

Description

Unlike non-standard cylinders, the cylinder is a track for piston movement. Gas burns and expands within it. Through the cylinder wall, some residual heat from the gas can be dissipated to maintain the working temperature of the engine. The types of cylinders are integrated and single-cast. Single castings are divided into dry and wet types. The piston rod is the most important load-bearing component in the cylinder. High carbon steel, hard chrome plating, or stainless steel is usually used to prevent corrosion and improve the wear resistance of the sealing ring. When the cylinder is working, the piston must be lubricated with oil mist from compressed air. There are also a small number of non-lubricated cylinders. The sealing of rotating or reciprocating parts of the cylinder sealing ring is called dynamic sealing, while the sealing of static moving parts is called static sealing. The connection methods of the cylinder barrel and end cover are as follows: integral, riveted, threaded connection, flange, and tie rod. In addition to static loads such as the pressure difference inside and outside the cylinder and the weight of various components, the cylinder also bears the reaction force from steam flowing out of the static blades and the forces acting on the cylinder from various connecting pipes under hot and cold conditions. Under the action of these forces, the cylinder is prone to plastic deformation and leakage.

Product Parameters

Model | JLB150T | JLB250T | JLB300T | JLB400T | JLB600T | JLB1000T | |

Maximum Pulling Force (KN) | 1630 | 2700 | 3200 | 4100 | 6500 | 12000 | |

Drawing Speed (M/min) | 0-5.5 | 0-4.5 | 0-4.5 | 0-4 | 0-3 | 0-3 | |

Effective Length of Finished Pipe (M) | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | |

Thickness of Finished Pipe (mm) | 20 | 25 | 30 | 33 | 42 | 70 | |

Main Cylinder (mm) | Φ320/Φ 150x10000 | Φ420/Φ 210x10000 | Φ450/Φ 210x10000 | Φ500/Φ 220x10000 | Φ630/Φ 280x10000 | Φ850/Φ 350x10000 | |

System Station Count (Station) | 2 | 2 | 2 | 2 | 2 | 2 | |

System Working Pressure (Mpa) | 26 | 26 | 26 | 26 | 26 | 26 | |

System Maximum Pressure (Mpa) | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | |

Pump (Manual Variable Plunger Pump) | 160Lx3 | 160Lx2 250Lx1 | 250Lx3 | 250Lx3 | 250Lx3 | 400Lx3 | |

Main Motor (KW) | 55x3 | 55x2 75x3 | 75x3 | 75x2 90x1 | 90x3 | 132x3 | |

Dimensions (WxHxL) | 1.6x1.4x42 | 1.7x1.5x44 | 1.7x1.5x44 | 1.9x1.8x45 | 2.1x2x45 | 2.65x2.65x60 | |

Weight (T) | 86 | 100 | 120 | 180 | 220 | 300 | |

Keyword:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products