CONTACT US

SHENLU HYDRAULIC

Tel: +86-0510-83050688

Tel: +86-0510-83959581

E-mail: sales@shenlu.net.cn

Description

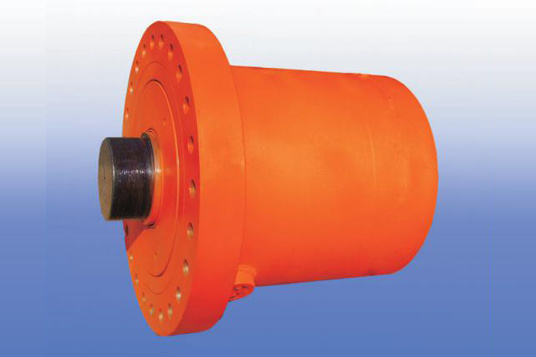

The precision piston rod is the most important load-bearing component in the cylinder. It is usually made of high carbon steel, with a surface treated by hard chrome plating, or made of stainless steel to prevent corrosion and improve the wear resistance of the sealing ring. The cylinder relies on the oil mist in the compressed air to lubricate the piston during operation. There are also a small number of non-lubricated cylinders. The rolling process of the piston rod is an efficient and high-quality process measure. By cutting the rolling head of Dr. Mirror with a diameter of 160mm, the rolling effect was verified. After rolling, the surface roughness of the cylindrical rod was reduced from Ra3.2-6.3 microns before rolling to Ra0.4-0.8 microns, the surface hardness of the cylindrical rod increased by about 30%, and the surface fatigue strength increased by 25%. The service life of the cylinder increased by 2-3 times, and the efficiency of the rolling process was about 15 times higher than that of the grinding process. The above data indicates that the rolling process is effective and can significantly improve the surface quality of the cylinder rod. The piston rod is formed by rolling, creating a cold work hardening layer on the rolled surface, which reduces the elastic-plastic deformation of the contact surface of the wear pair, thereby improving the wear resistance of the cylinder rod surface and avoiding burns caused by grinding. The surface roughness after rolling is reduced, improving the matching performance.

Product Parameters

Model | JLB150T | JLB250T | JLB300T | JLB400T | JLB600T | JLB1000T | |

Maximum Pulling Force (KN) | 1630 | 2700 | 3200 | 4100 | 6500 | 12000 | |

Drawing Speed (M/min) | 0-5.5 | 0-4.5 | 0-4.5 | 0-4 | 0-3 | 0-3 | |

Effective Length of Finished Pipe (M) | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | |

Finished Pipe Drawing Thickness (mm) | 20 | 25 | 30 | 33 | 42 | 70 | |

Main Oil Cylinder (mm) | Φ320/Φ 150x10000 | Φ420/Φ 210x10000 | Φ450/Φ 210x10000 | Φ500/Φ 220x10000 | Φ630/Φ 280x10000 | Φ850/Φ 350x10000 | |

System Station Count (Station) | 2 | 2 | 2 | 2 | 2 | 2 | |

System Working Pressure (Mpa) | 26 | 26 | 26 | 26 | 26 | 26 | |

System Maximum Pressure (Mpa) | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | |

Pump (Manual Variable Plunger Pump) | 160Lx3 | 160Lx2 250Lx1 | 250Lx3 | 250Lx3 | 250Lx3 | 400Lx3 | |

Main Motor (KW) | 55x3 | 55x2 75x3 | 75x3 | 75x2 90x1 | 90x3 | 132x3 | |

Dimensions (WxHxL) | 1.6x1.4x42 | 1.7x1.5x44 | 1.7x1.5x44 | 1.9x1.8x45 | 2.1x2x45 | 2.65x2.65x60 | |

Weight (T) | 86 | 100 | 120 | 180 | 220 | 300 | |

Keyword:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products